The centerbore (or commonly called hub-bore) of a wheel is the machined opening on the back of the wheel that centers the wheel properly on the hub of a vehicle. This hole is machined to exactly match the hub so the wheels are precisely positioned as the lug hardware is torqued down. Keeping the wheel precisely centered on the hub when it is mounted will minimize the chance of a vibration. Some wheels are vehicle model specific and will come from the factory with a bore machined to match that vehicle. Some wheels are designed to fit multiple vehicle models (like our Dual-Drill UTV Wheels) to maximize a single wheel with two bolt patterns, both 4x137 AND 4x156

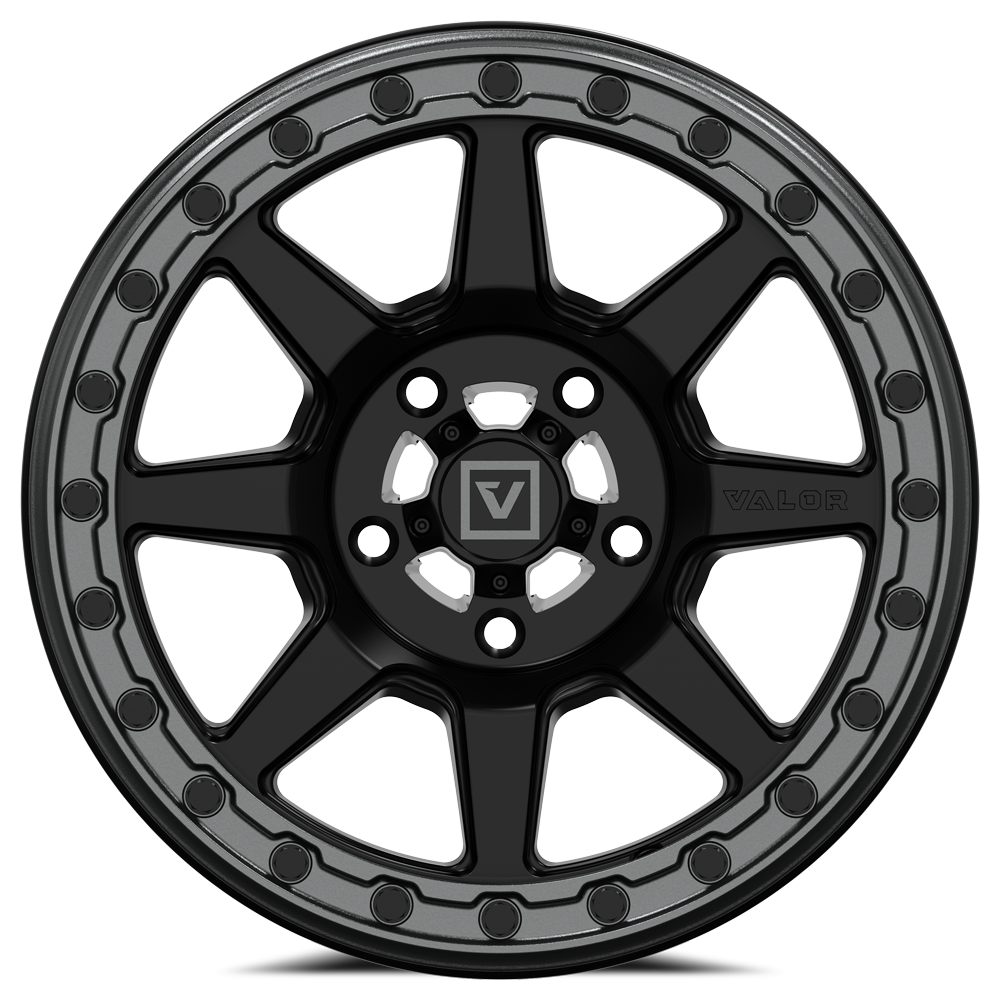

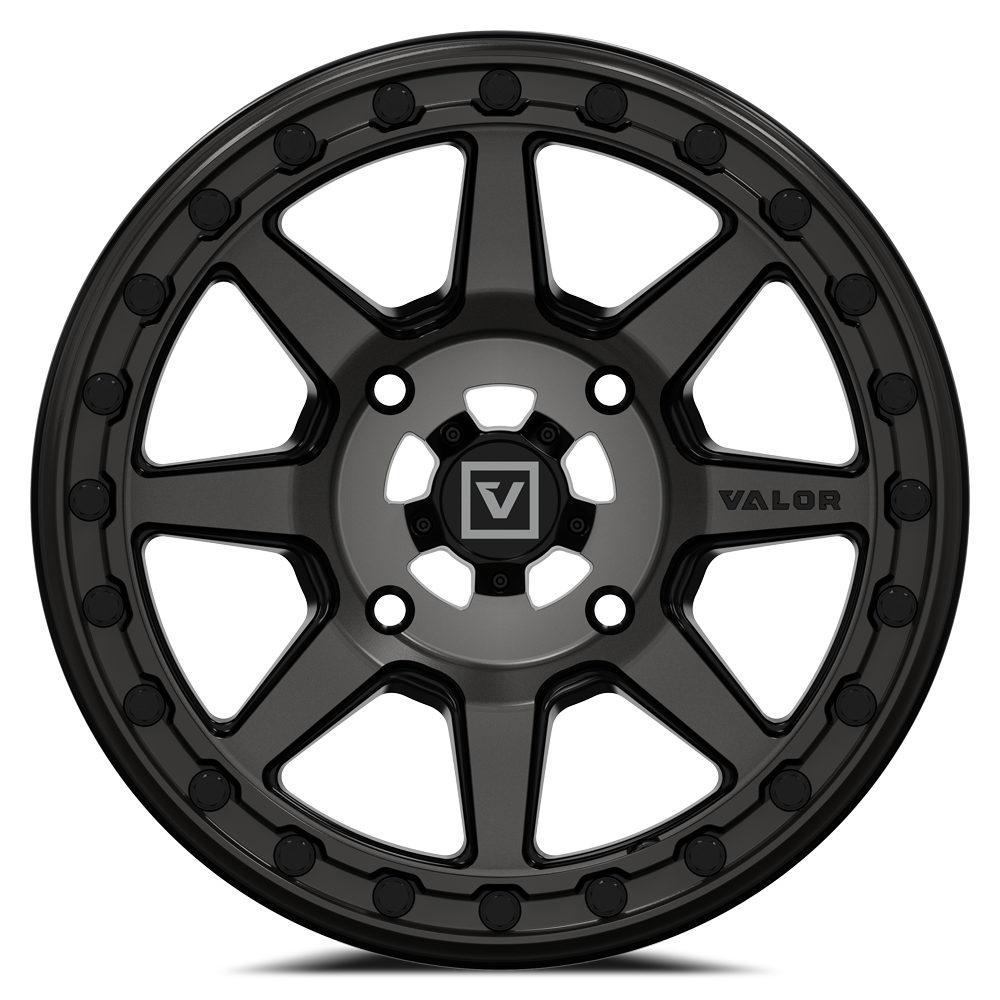

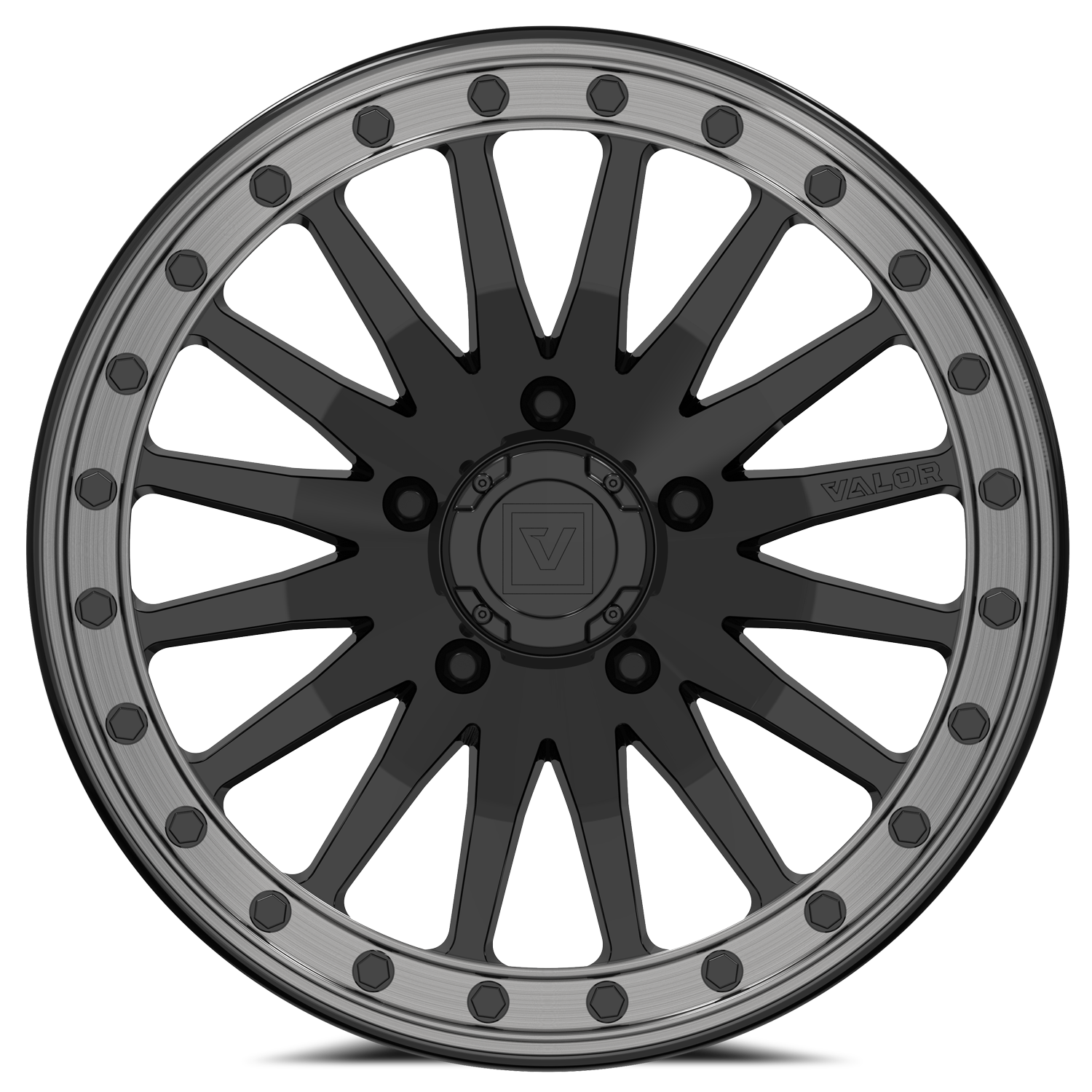

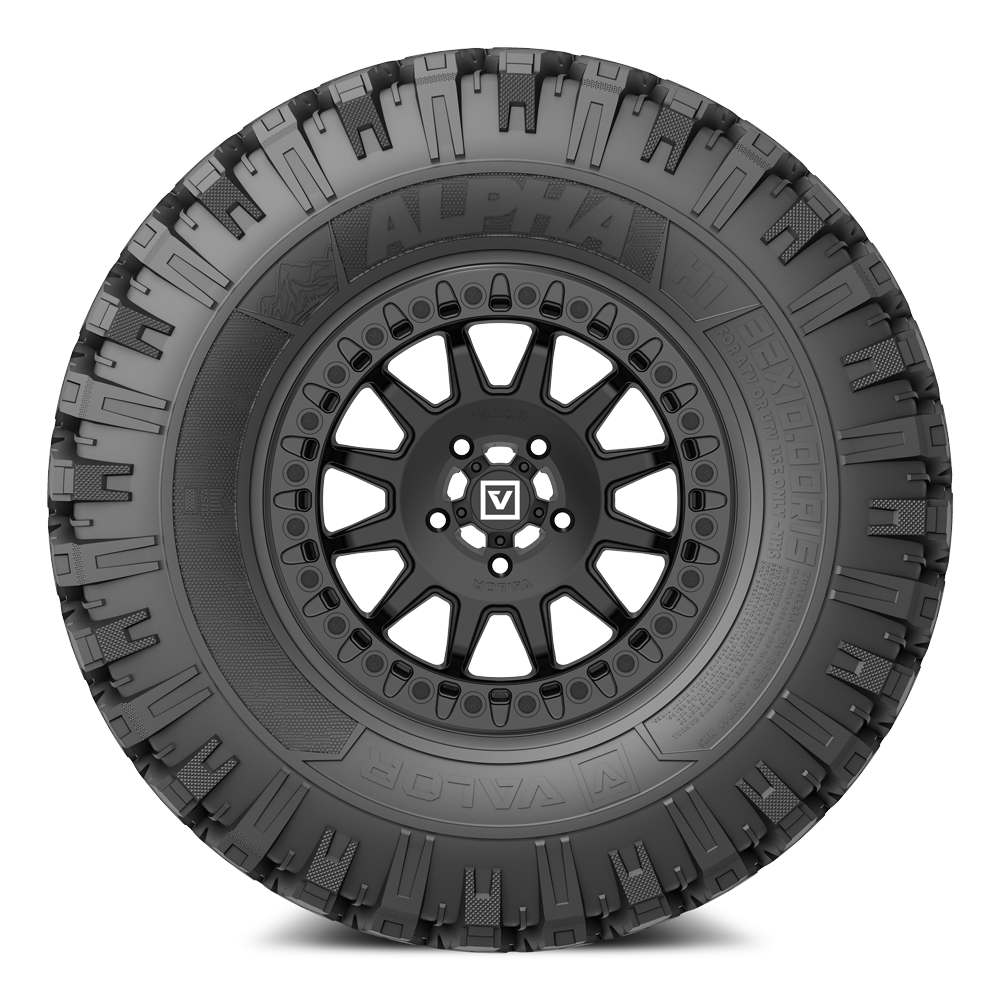

Wheel Example Below: V01 15x7 4x156

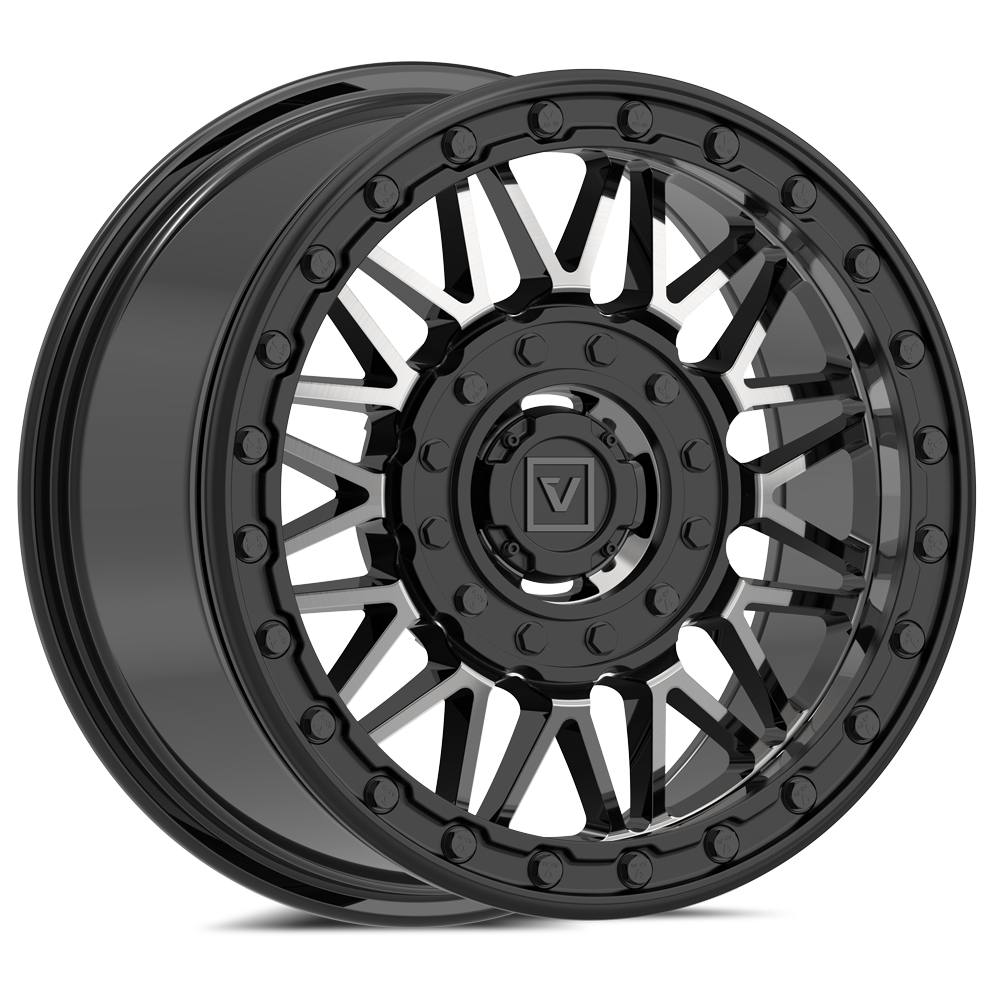

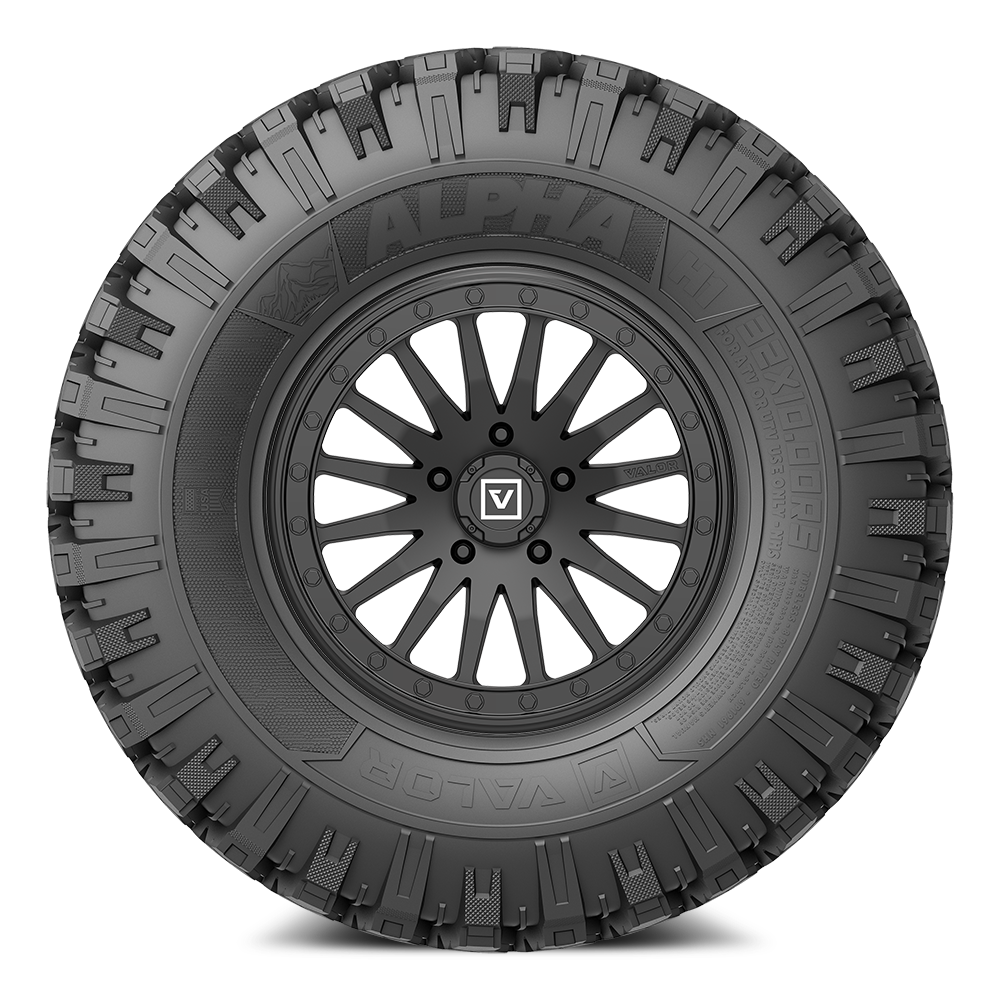

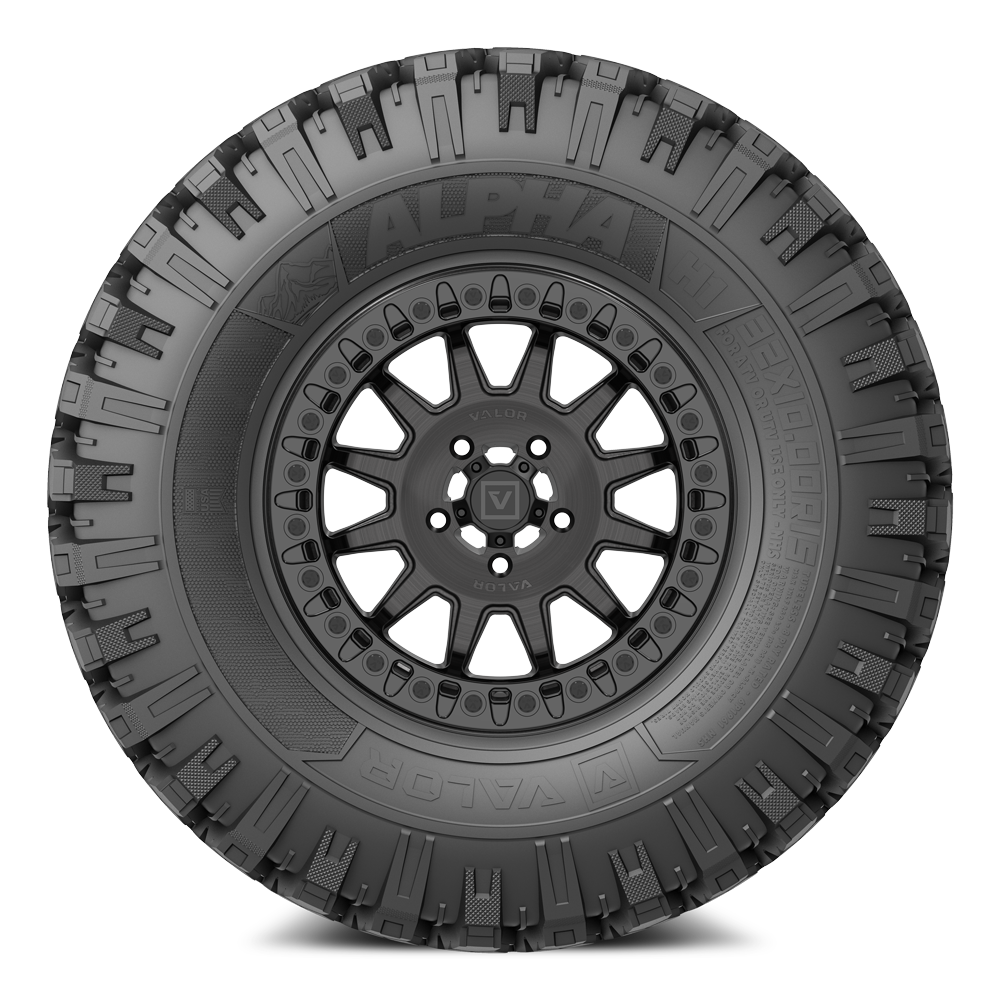

Polaris is notorious for having the largest hub assembly in the powersports industry, and thus requiring a very large centerbore measurement. For comparison, the Polaris 4x156 bolt pattern requires a 132mm (5.20") centerbore, while a Honda 4x110 bolt pattern requires a 86mm (3.38") centerbore. In the image below, there are two highlighted sections for reference. The blue area is the cap and the pink area is the centerbore. The centerbore of a wheel is machined during the manfacturing per the bolt pattern requirements so each Valor Offroad wheel is specifically engineered to work for your make/model of UTV or ATV.

Valor centerbore specs:

| Bolt Pattern | Centerbore |

| 4x110 | 86mm |

| 4x137 | 112mm |

| 4x156 | 132mm |

Note: It is critical to torque the lug hardware with the vehicle on jack stands, off the ground. This allows the nuts or bolts to center the wheel and torque down without the weight of the vehicle pushing them off center.

View full valor offroad spec list here